Moulded thermoplastic composites; lightweight and recyclable. The BCPR project.

- Nacar Design Team

Layered thermoset composites, such as "carbon", are frequently chosen over aluminum or steel for structural components that require both lightness and design freedom. A very well known example of this are bicycle frames, but many examples exist such as wheelchair frames and drones. Thermoplastic composites, despite being rigid and lightweight, are not considered recyclable. Due to labor intensive manufacturing processes, almost all carbon bicycle frames are produced in regions with a low-wage workforce.

Thermoplastic composites

Unlike thermoset composites, thermoplastic composites offer a realistic path to a circular economy. They are moldable, for example through injection molding and gas or water-assisted molding. These production methods require minimal labor, making it suitable for manufacturing in Europe. At the end of their lifespan, thermoplastic composites can be shredded and re-molded.

The BCPR project

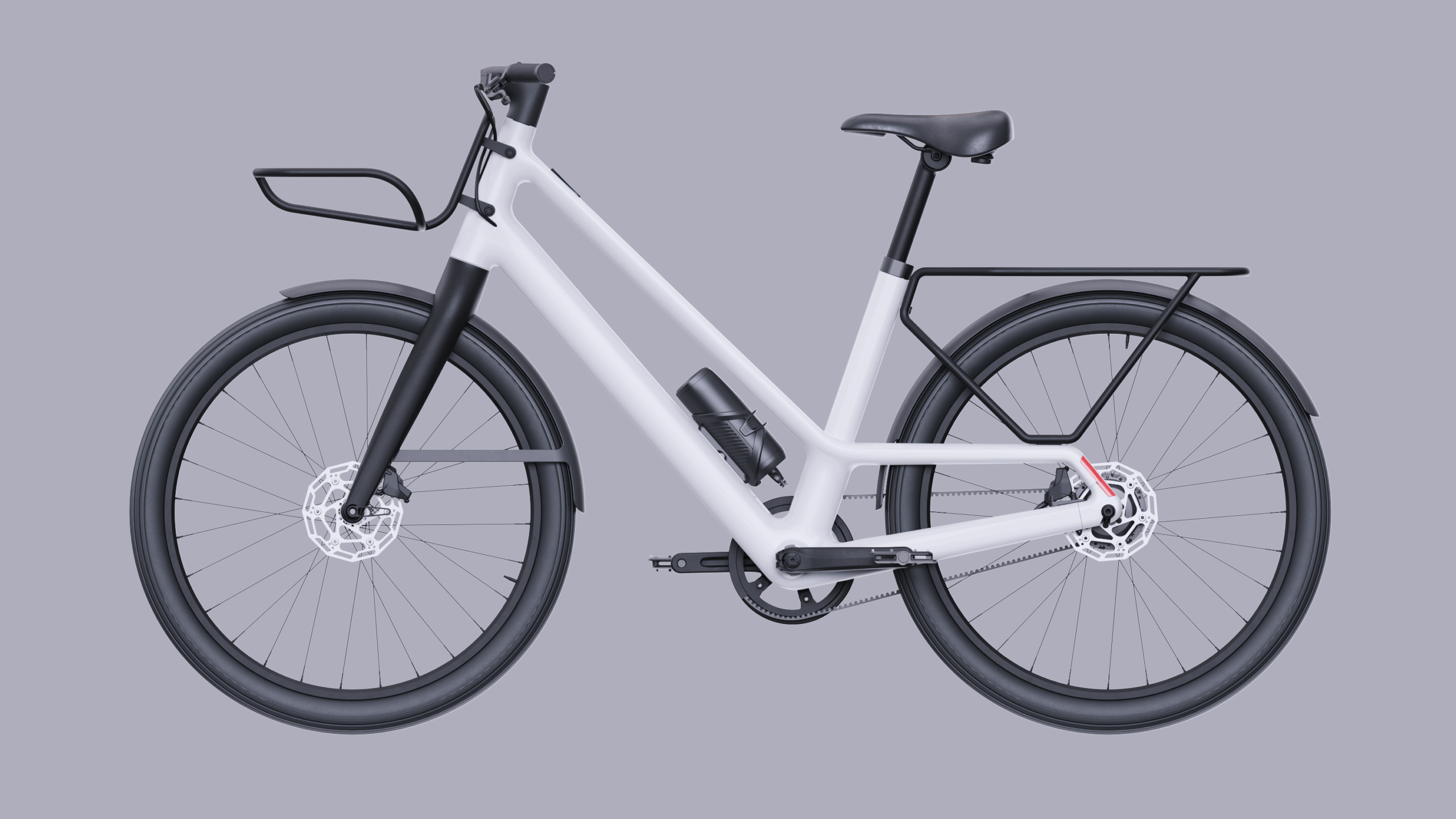

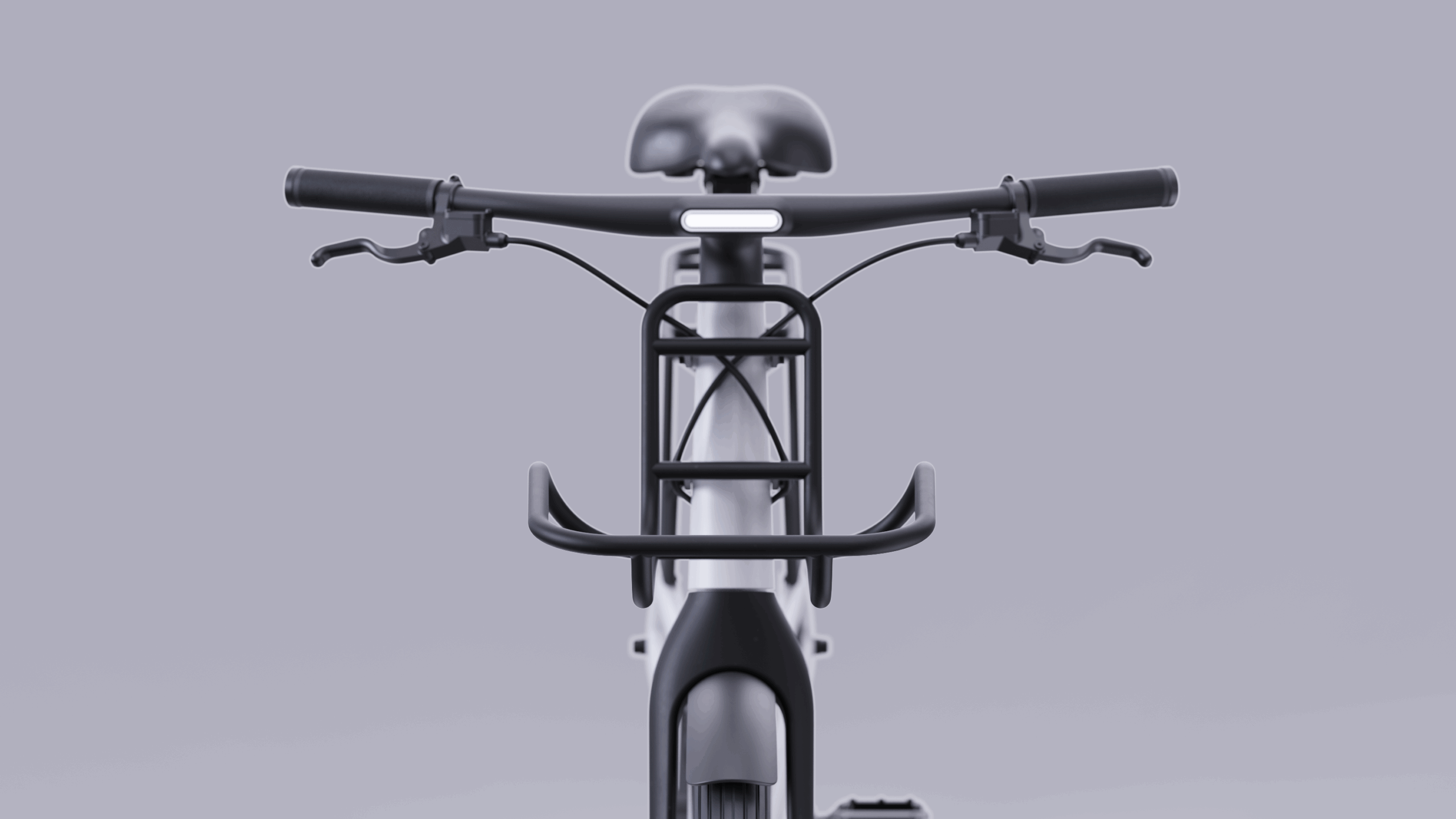

Nacar Design designed a Ebike with a recyclable thermoplastic composite frame. This R&D project, which is called BCPR (bicicleta con cuadro de plástico reciclable - bicycle with recyclable plastic frame), includes technology, market and user-research, design, prototyping and validation. Various e-bike architectures were explored during the project. For the South European market, we designed a lightweight, cost-effective, and highly functional e-bike. Its frame is constructed from a small number of injection-molded shells, welded together, with integrated mechanical and electrical cabling. The e-bike frame can be manufactured using carbon fiber-filled polyamide compounds, resulting in an 18-19kg e-bike. Recycled carbon fiber can be sourced from discarded aerogenerator wings, and recycled polyamide from discarded clothing and fishing nets. Downstream, discarded BCPR frames can be shredded and repurposed for less critical structural components, such as car interior parts and accessories for the BCPR. Research is ongoing regarding the use of glass fiber-filled polyamide compound, as it offers a more cost-effective solution with a lower environmental impact.

The BCPR project was carried out between September 2024 and May 2025 with the support of ACCIÓ and the ARC, within the framework of subsidies for R&D projects in the circular economy in the field of waste 2023 (subvencions a projectes R+D en economia circular en l’àmbit dels residus de l’any 2023).

Compuestos termoplásticos moldeados; ligeros y reciclables. El proyecto BCPR.