Redefiniendo la interacción entre maquinaria CNC

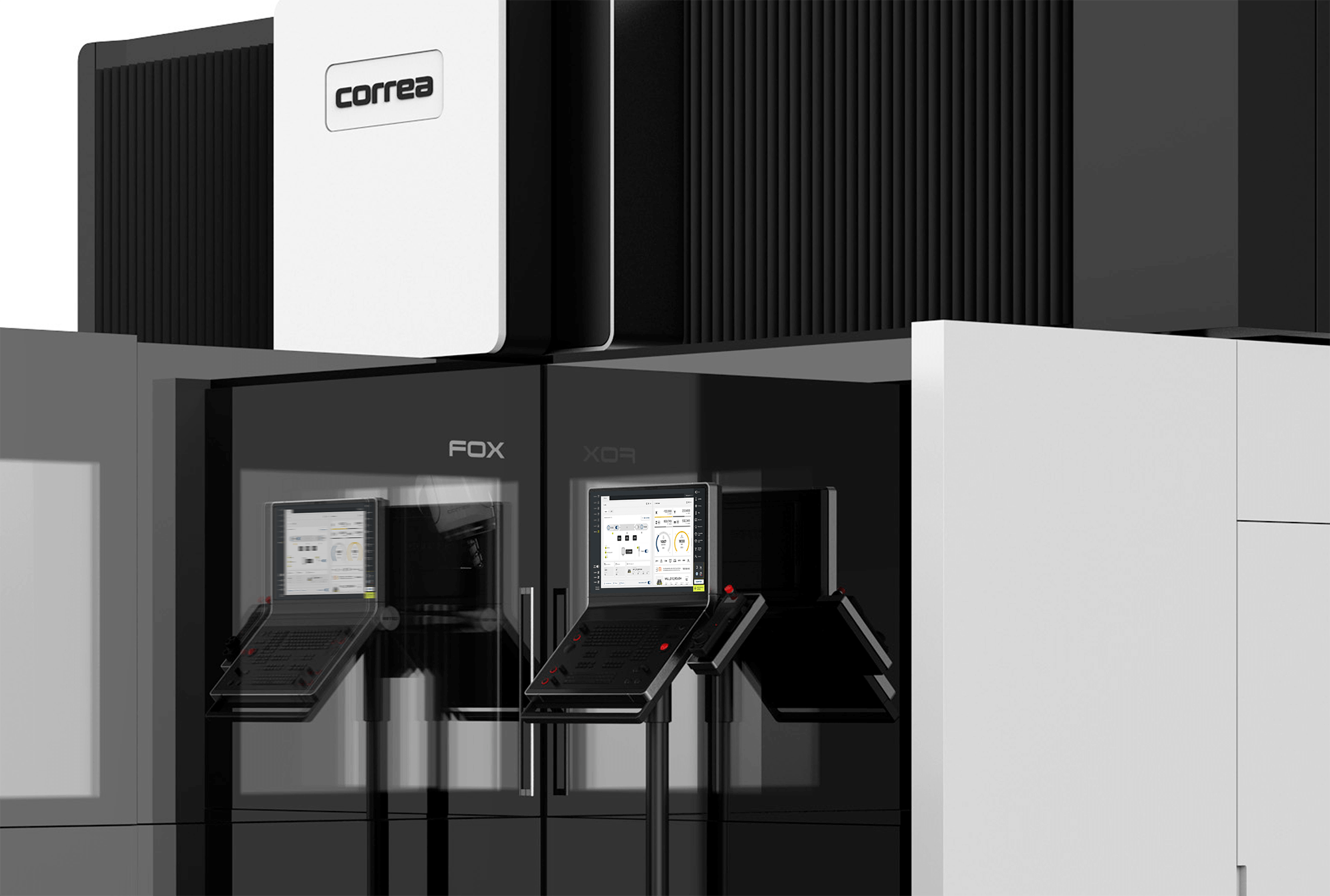

HMI Design System con Correa

Mejorar las experiencias del operador y el mantenimiento con soluciones de diseño HMI centradas en el usuario, impulsadas por un sistema de diseño sólido y mejoras intuitivas en la interfaz de usuario.

Optimización de la interfaz de usuario para las máquinas CNC de Nicolás Correa con Design System e integración HMI, atendiendo a operadores y proveedores de mantenimiento.

Design Sprint iniciado para perfeccionar las soluciones, aprovechando los conocimientos de los usuarios y Design System para lograr coherencia. HMIs a la medida de las necesidades de Correa.

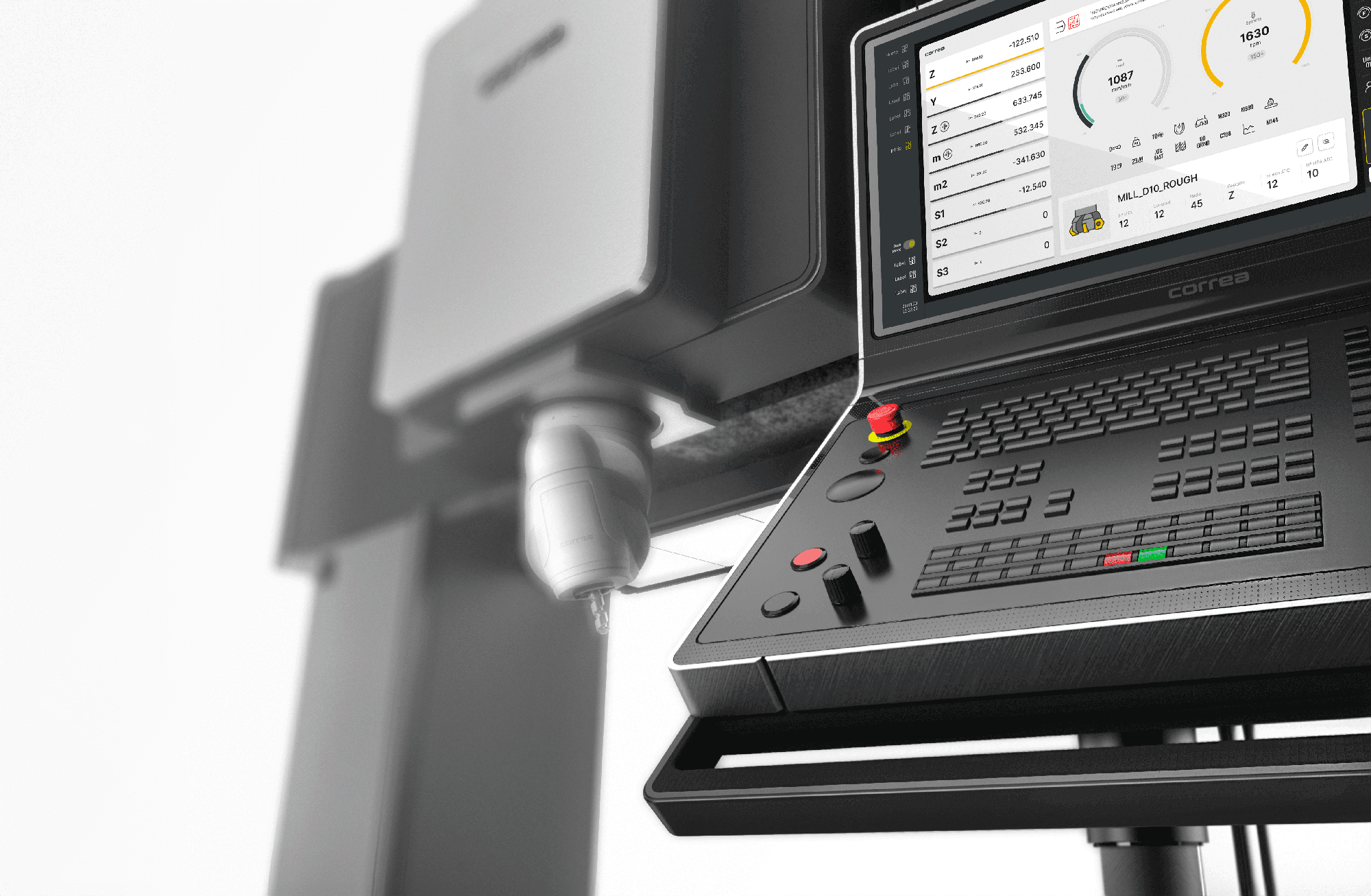

Capacidades mejoradas de la máquina CNC y usabilidad de HMI. La evaluación cubrió planes de diseño, menús, controles y más. La metodología aseguró un progreso eficiente.

- UX/UI

- Visual Design

- Diseño de interacción

- Experiencia de usuario

Optimización de la interfaz de usuario para la excelencia CNC

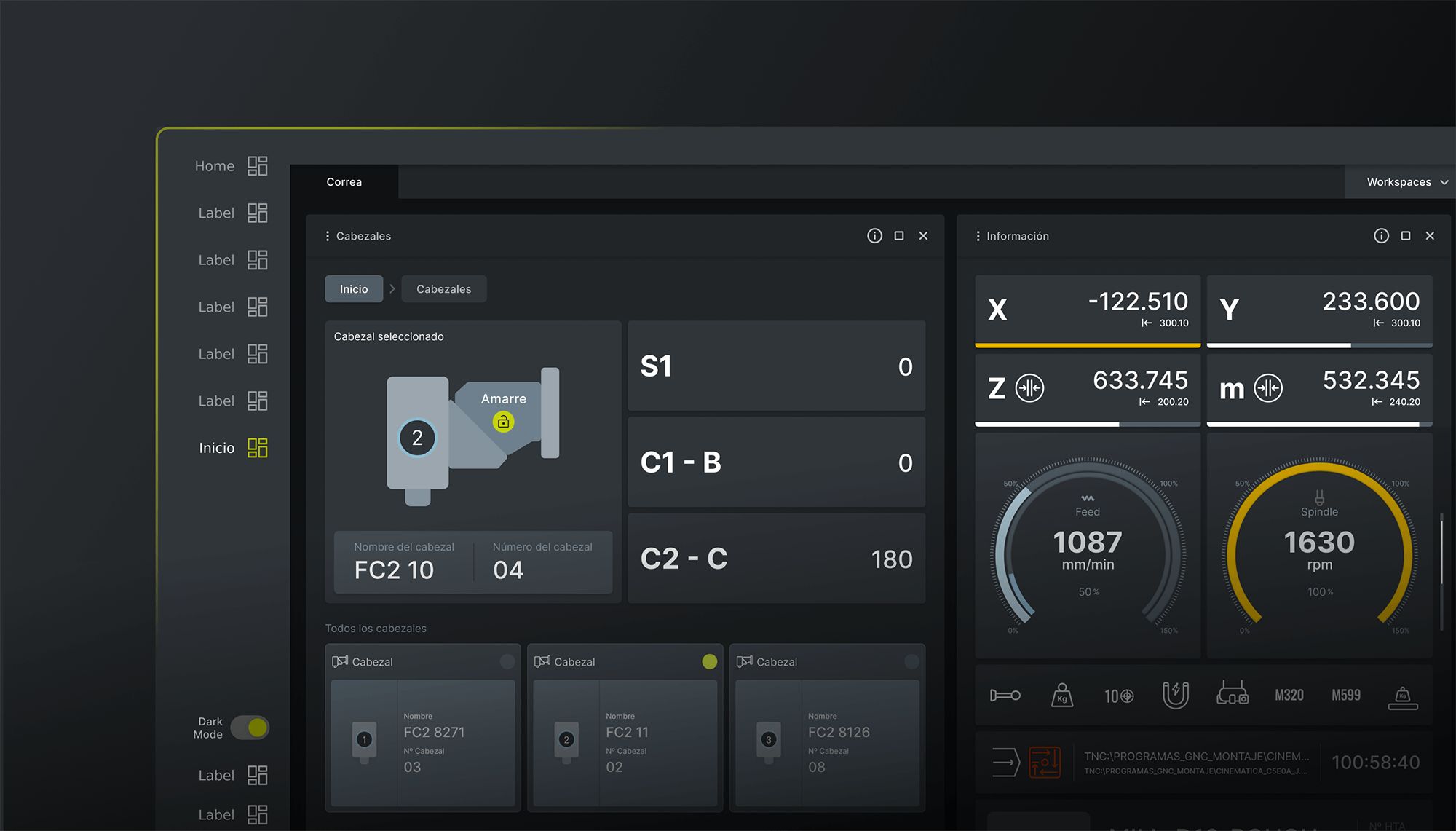

Nuestro principal objetivo fue mejorar la UX/UI de las fresadoras CNC de Nicolás Correa integrando un Sistema de Diseño integral y optimizando las Interfaces Hombre-Máquina (HMI). Nuestro objetivo era refinar la experiencia del usuario con el nuevo modelo y al mismo tiempo garantizar la coherencia de la marca y la usabilidad práctica, enfocándonos en satisfacer las necesidades de los operadores y proveedores de mantenimiento adaptando el enfoque de diseño al flujo de trabajo CNC.

Soluciones moldeadas por los conocimientos del usuario

Iniciamos un Design Sprint para agilizar el desarrollo, analizando los viajes de los usuarios, abordando los puntos débiles y creando rápidamente prototipos para perfeccionar las soluciones. El empleo de un sistema de diseño garantizó coherencia y una experiencia de usuario coherente. La integración de HMI mejoró la usabilidad y cumplió con las necesidades del equipo de Nicolás Correa. Las actividades incluyeron estudios de flujo de trabajo, colaboración con los operadores y administradores de Correa.

Iniciativas de mejora impulsadas por el usuario

Al alinearse con los recorridos de los usuarios, identificar casos de uso y abordar limitaciones técnicas, como la navegación y la distribución interactiva de componentes, el proyecto tenía como objetivo maximizar las capacidades de las máquinas CNC y las HMI asociadas. La evaluación abarcó planos de diseño, menús, controles, vistas actuales de la página de inicio, manejo de máquinas y gestión de herramientas, entre otras funcionalidades. Dirigido a operadores y proveedores de mantenimiento, el proyecto utilizó una metodología dividida en horizontes y ciclos de sprint para garantizar un progreso y una entrega eficientes.