Modularity in Motion

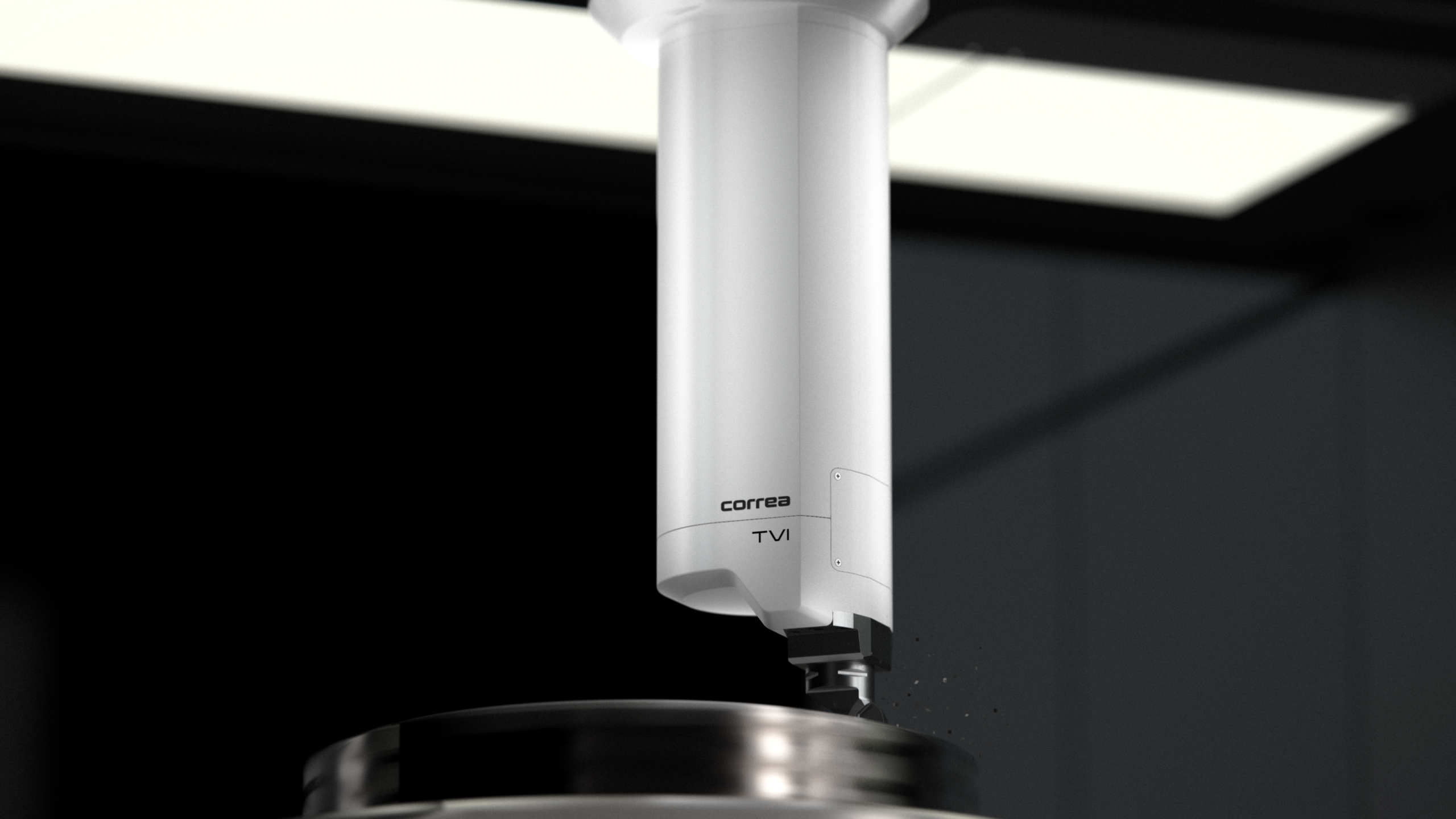

TH & TV heads with Correa

Rethinking CNC tooling for vertical and

horizontal versatility

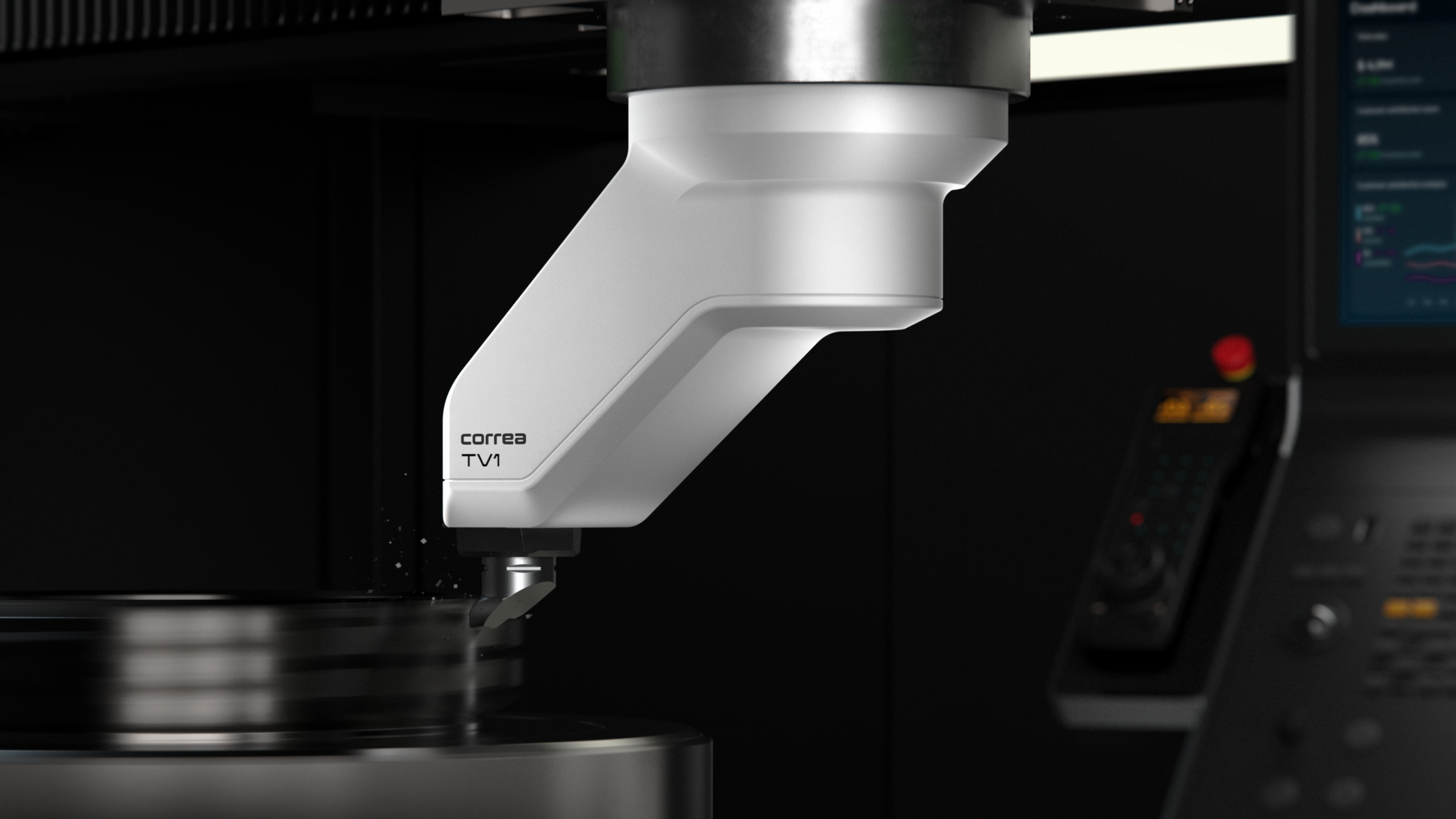

Creating a CNC head family capable of adapting to multiple spindle orientations without compromising rigidity, accuracy or ease of use, while unifying engineering and industrial design.

A four-model head system engineered with shared components, consistent interface logic and distinct visual identity. Designed for clarity, durability and seamless machine integration.

Correa’s modular approach to CNC heads reduces operational friction, enhances tooling efficiency and sets a new reference in the category of high-performance mechanical interfaces.

- Market & Trend Research

- Visual Brand & Design Language

- Product Strategy

- Conceptualization & 3D Modeling

- Design for Manufacturing

- VR

Flexibility without compromise

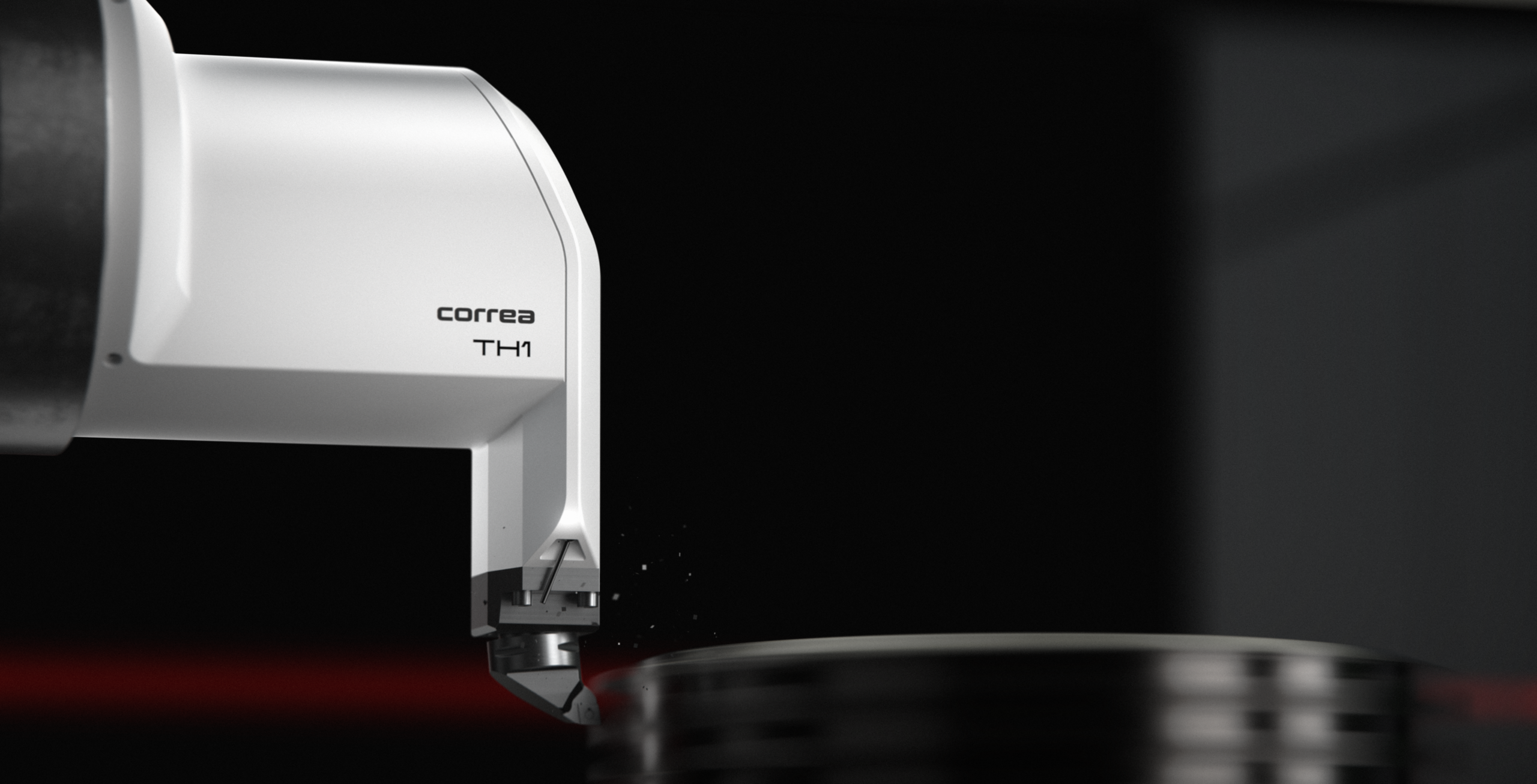

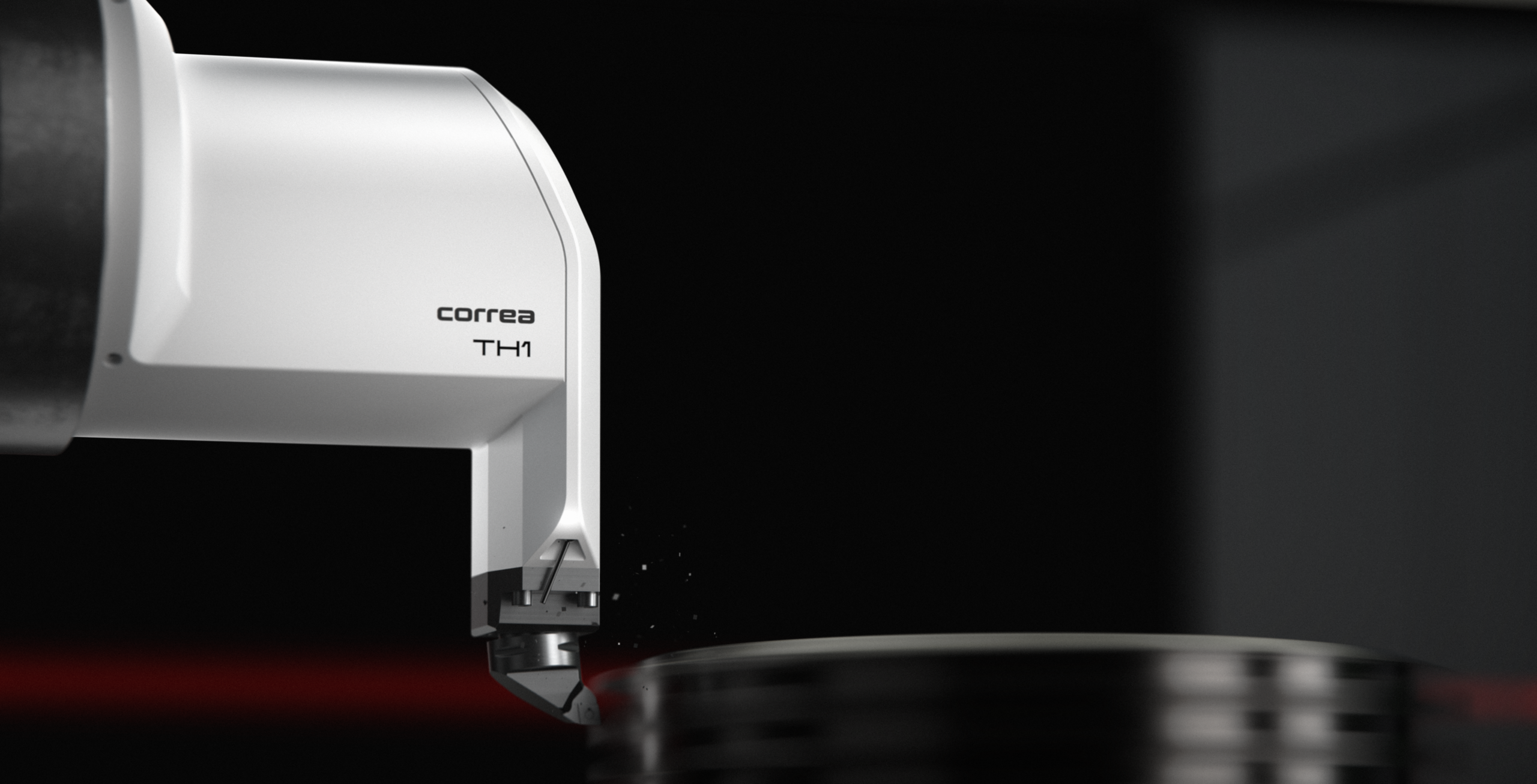

Correa sought a CNC head solution adaptable to both vertical and horizontal spindle mounts, without duplicating engineering or increasing production complexity. The aim was to develop a modular platform that ensured mechanical precision, ease of integration and manufacturing efficiency.

A coherent system for complex operations

We designed a modular head system composed of four models with shared components and unified structural logic. The design enhances mechanical legibility, facilitates maintenance and preserves rigidity under demanding machining conditions, all within a consistent industrial brand language.

A smarter interface between machine and material

Correa’s TH & TV heads introduce a modular CNC tooling system that reduces setup time, simplifies maintenance and lowers tooling inventory. Backed by industry data, modular architectures are proven to cut operational costs and extend service life by enabling selective part replacement. This system brings added flexibility without compromising precision, helping Correa’s clients meet evolving production demands with efficiency, clarity and long-term value.